Calibrating the FarmTRX Yield Monitor is a straightforward process that gets you accurate yield data readings in the cab while at harvest. Our goal for FarmTRX is to stay out of the way when it comes time to harvest, so if your combine operator forgets or doesn’t have time to perform a calibration before harvesting, you can always get accurate yield maps after the fact by post-harvest calibrating the yield data through the FarmTRX Web Application. As long as the Yield Monitor is powered on and the yield sensor LEDs are flashing green, yield data variation is being measured and farmers can get accurate yield maps.

To get the Yield Monitor set up for harvest, farmers should first complete a sensor calibration in the yard at the time of install, or whenever a change to the combine elevator chain has occurred. FarmTRX uses optical yield sensors installed on the elevator. This sensor calibration process tares the combine so the elevator paddle width is measured when no grain is travelling through the elevator.

If you want to see accurate live harvesting data in the cab on your mobile device, a crop calibration should be completed in the mobile app for each new crop type harvested. We suggest doing this every season for best results.

Here are the steps to calibrating the Yield Monitor in the yard and in the field:

IN THE YARD PRE-HARVESTING

Verify yield monitor installation:

As part of your harvest preparation, it’s important to look over your Yield Monitor installation and verify everything is connected. Here’s how to verify your installation with a visual check:

- Examine the wiring routing path from the Yield Monitor located in the cab, to the sensors located on the clean grain elevator. Make sure all wires are away from any moving belts or parts of the combine.

- The Yield Monitor Electronic Control Unit (ECU) located in the cab has a status LED. If the light is flashing green the monitor is functional and not yet collecting valid sensor data. If the light is solid green, the monitor is functional and collecting valid sensor data.

- Check the LEDs on the yield sensor installed on the outward face of the elevator. The left LED indicates power supply and will be green if powered. The right LED indicates pulse, and will pulse if the light beam between the two sensors is momentarily blocked ie. the thresher is engaged and the elevator is moving. Manually advance the elevator chain to confirm the right LED will flash when the sensor light is blocked.

Complete sensor calibration in the mobile app:

- Next you will need to conduct a sensor calibration through the mobile app. The sensor calibration tares the combine, telling the Yield Monitor the width of the elevator paddles when no grain is travelling up the elevator.

- Connect to the Yield Monitor in the FarmTRX mobile app

- From the Connection page of the app, press “Connect” on the Yield Monitor name being used

- If the firmware requires update, press “OK” on the update notification

- Wait for the update to complete. Do not disconnect from the Yield Monitor or turn off your device. You will need to reconnect the Yield Monitor after the update.

- When connection is successful, you will be directed to the Live Harvesting screen.

If it is the first time you are getting set-up in the FarmTRX app, add your combine headers and crop types at this point. More information on how to do that here.

- Conduct a Sensor calibration

- Navigate to the Device Calibration page

- Press “START CALIBRATION” under Sensor Calibration

- Press the box beside each condition (a checkmark will appear) once each condition is met

- Press “Ready” to start the calibration

- When the calibration has finished, press “Complete”

- If calibration was unsuccessful, an error message will appear. Make sure your optical sensors are properly installed and the combine is stationary and running at full throttle with the threshing clutch engaged.

Setup of the Yield Monitor from the yard is complete! If you want accurate live yield readings in the cab, you will need to conduct a crop calibration per crop type harvested. It’s part of the FarmTRX mandate to stay out of the way at harvest time. So if you cannot complete a crop calibration while harvesting, don’t worry. The yield monitor is always recording relative differences in yield.

In the Web Application, farmers can add in their total yield for the field after-the-fact, and FarmTRX reprocesses the data into accurate and agronomy-ready maps.

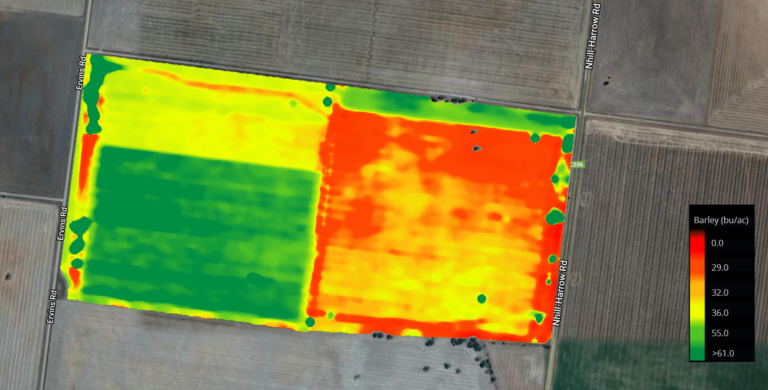

Raw yield data with 3 separate calibrations for the field

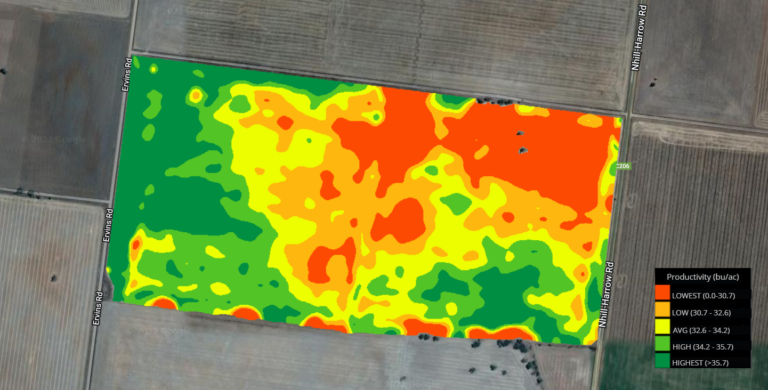

Automatic yield data correction using post-harvest calibration

IN THE FIELD AT HARVEST

Crop Calibration:

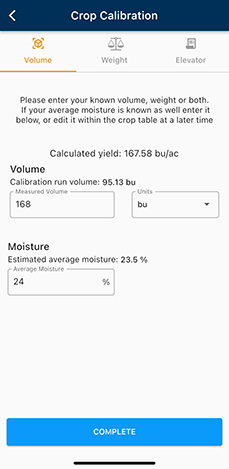

Crop calibrations are done by volume or weight. A volume sample (like harvesting a hopper–full) will get you within +/- 5% bushel accuracy. For greater accuracy, use a larger representative sample and a weight measurement (using weigh wagons or truck/grain cart with scales). The most accurate will be adding the elevator field totals directly into the Web App after harvest and post-harvest calibrating the recorded data.

- Set the processing delay

- Press “Edit Delay” under Device Calibration in the FarmTRX mobile app

- Enter the processing delay (time from cutting head of the combine to sensor measurement, eg. 10 seconds or time from cutting head to sensor reading/value display).

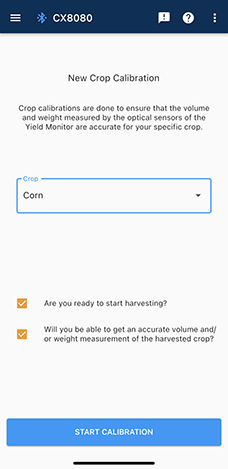

- Complete crop calibration

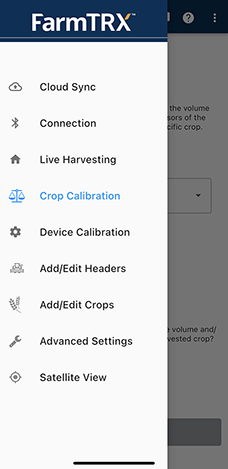

- When you know you can get a measurable (by volume or weight) sample of the field, navigate to the Crop Calibration page from the main menu of the mobile app

- Ensure all listed conditions are met and press their associated checkbox

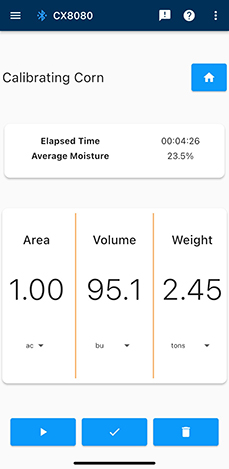

- Press “Start Calibration” and begin harvesting

- Press “Pause” as soon as harvest is unloaded. Enter the measured weight and/or volume along with measured moisture (if available/applicable)

If you have a companion Moisture Sensor from FarmTRX installed:

-

- Obtain a moisture sample while harvesting

- Press “Edit Average” on the Crop Calibration screen

- Enter the measured values from the sample

Don’t forget! A miscalibration or no calibration at all does not affect your ability to get accurate maps for the field after harvest. You can post-harvest calibrate the yield data after the fact in the Web App.

This information will get you covered for beginning to harvest with the FarmTRX yield monitor! As always, don’t hesitate to reach out to us at info@farmtrx.com with any questions or for more information on yield mapping with FarmTRX.